Laser cutters may seem like a complicated new technology involving CO2 gas and laser beams, but they’re actually an amazing tool for prototyping and design in education. Just like 3D printers have been growing in popularity and accessibility in recent years, laser cutters are making their way into the tech classroom.

The most popular form of laser cutter, and the category the InkSmith Mako falls under, is the CO2 or Carbon Dioxide laser. The CO2 laser cutter consist of a glass tube filled with CO2 gas, which when combined with electricity, creates an infrared laser beam.

Compared to 3D printing, laser cutters are a much faster method of prototyping. 3D printing works by extruding layers of melted plastic, layer by layer until the three-dimensional object is complete. This process, while the best option for some prototypes, can be quite time-consuming. Whereas, with laser cutting, a 2D dimensional shape can be cut out in a matter of minutes.

Don’t get us wrong, 3D printing is an amazing technology and serves a great purpose for certain prototyping and design projects. 3D printing is especially useful for creating precise mechanical parts, or diagrams, things that would be difficult to achieve with wood or acrylic. In fact, when 3D printing technology and laser cutting are combined, the design and prototyping possibilities are endless.

Just like 3D printing, in order to create something with the laser cutter, you’ll need to start with a design file. You can create this file yourself or download one from an open-source platform. Once you have the design file, you’ll need to determine the necessary power settings depending on what material you are cutting/engraving. These power settings will change depending on how thick the material is, what it’s made out of, and what sort of cutting/engraving effect you’re trying to achieve.

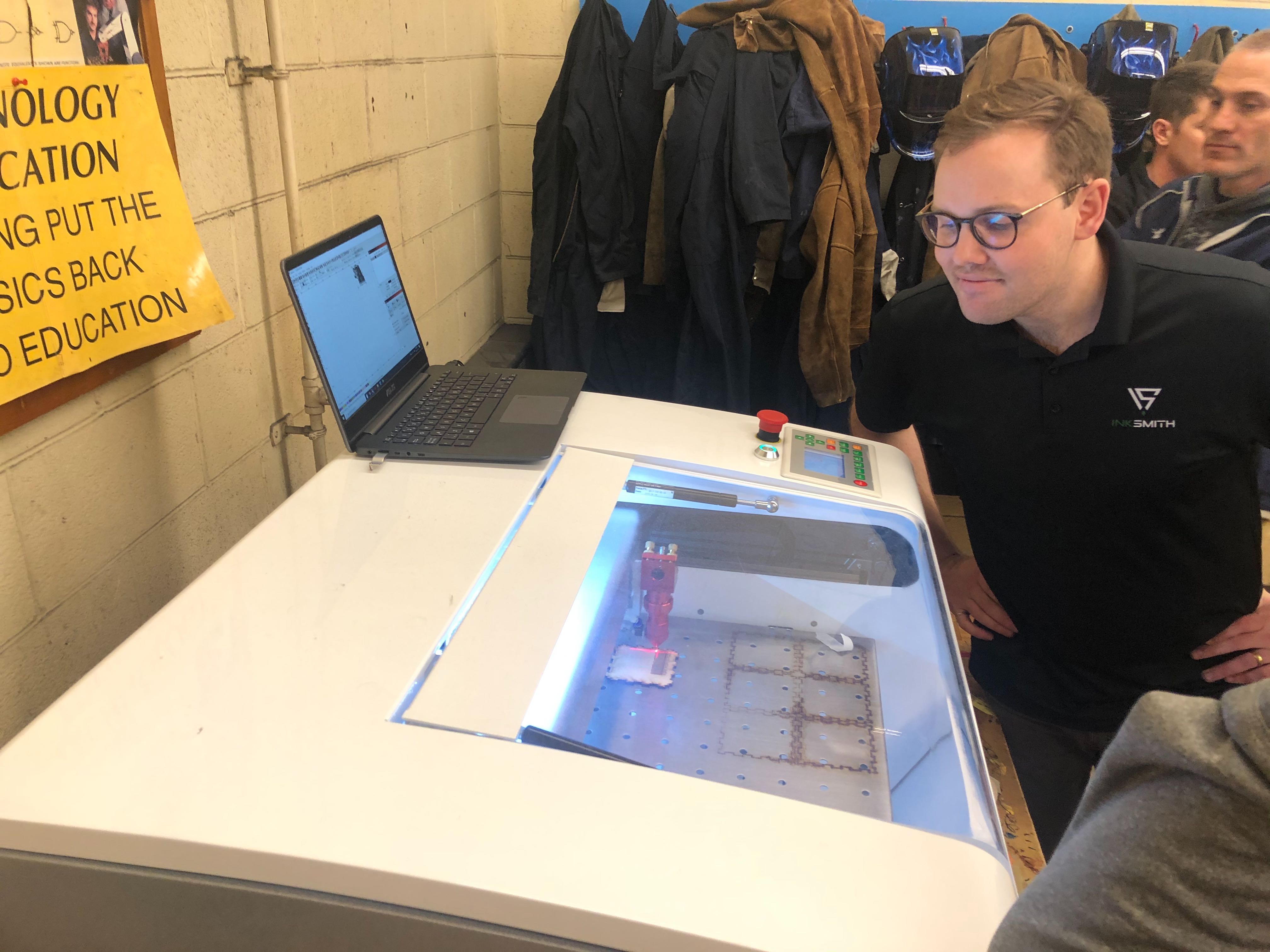

Laser cutters come in a variety of power levels, anywhere from 40W up to 100W. The InkSmith Mako comes in a 40W and 80W versions. The power level of the machine will determine the length of the laser tube and therefore the cutting power capabilities. The complete laser cutting system is made up of a few main components, the laser cutter machine including the CO2 laser tube, a water chiller, an air compressor and some sort of ventilation system.

For simplicity, the actual laser cutter consists of the CO2 laser tube, 3 reflection mirrors, a focusing nozzle and a cutting bed. When fired, electricity flows through the laser tube, is bounced off of 3 mirrors, focused into a concentrated beam and then burns into the material on the cutting bed.

Now you’re probably wondering what sort of things can you make with a laser cutter? The short answer is basically anything you can imagine. While laser cutting must be done on a flat 2D surface, these 2D pieces can be combined to create any number of three-dimensional objects.

Laser cutting, like 3D printing, is an amazing way to exercise design thinking skills. No matter what you’re trying to create with laser cutting, you have to think about how each of the pieces will cut and how they will be combined together. You have to think about what type of material you’ll be using and how that will affect the design, power settings and so on.

Laser cutting is also a great introduction to different methods of manufacturing and fabrication. Being able to understand the design process to go from an idea to actually laser cutting will undoubtedly be a useful skill for students in the future.

Whether you choose to take the design thinking approach to laser cutting or the more industrial approach, the skills learned from this process are sure to be applicable across many different subjects for students.

Below are some different examples of how laser cutting can be incorporated into a range of different school subjects. Regardless of how which project you actually choose to do, laser cutting is sure to make a huge impact on student learning and engagement.

Laser cutters don’t have to be scary! Implementing this type of technology into your school’s tech classroom can open up a world of creativity for students. It also gives students access to a tool they likely wouldn’t have had the opportunity to explore otherwise.

If you’re intrigued about the idea of integrating a laser cutter into education and want to learn more, we’ve put together some introductory videos you can check out below. These videos will demonstrate how the laser cutter actually works, how each of the laser cutting components is connected, and how to actually use the machine.

Mako Laser Cutter Tutorial Part 1: Introduction

4000 Trees Planted from Climate Action Kit Pre-Sales

InkSmith Adds MERGE to Virtual Reality Product Offerings